All About Winch Cable

- Why You Shouldn't Use Chain for Off Road Recovery

- 6 Reasons Tow Straps with Hooks Will Kill You

- Winch Database

- Strength

- Flexibility

- Weight

Almost every winch today comes with steel winch cable from the factory. But did you know that your winch cable is delicate and underrated for winching? Probably not, and this is one reason why we use recovery dampers. There are reasons winch cable is small and ways to keep it lasting longer.

Let's first say that you are ultimately responsible for your recovery

gear. People get hurt and killed in recovery operations. There are

massive forces and weights involved in recovery operations, so care for

your gear, know your gear, respect the boundaries of your gear, read

about recovery setups, and practice your skills.

Being safe in recovery operations isn't complicated. It's simply about not making mistakes - don't hook your winch cable on itself, make sure your recovery points are strong, don't overload your winch cable, etc.

One thing you should understand about your recovery gear is that there is no governing body that tells you how to winch, or how to rig your snatch blocks, or what size bolts your recovery points should use. That's all up to you and the manufacturers that you trust. Some of the gear used in 4x4 recovery operations is also used in hoisting and lifting. Hoisting and lifting do have governing organizations that say how to do things and how things should be rated.

Below, we're going to walk through cable characteristics and "build" a cable that we can use on our winch.

Working Load Limit vs. Minimum Breaking Strength

Working Load Limit (WLL), is maximum allowable weight. If that isn't clear, cable manufacturers are saying, "Don't ever put more than X weight on this cable."

Working Load Limit is determined using the Minimum Breaking Strength (MBS). For wire rope that we use in winch cables the WLL is 1/5 the Minimum Breaking Strength. Put another way:

Working Load Limit x 5 = Minimum Breaking Strength

The "5" in the equation above is called the Design Factor. In hoisting, design factors are for when Kevin screws up the rigging and overloads a component. The design factor ensures that the I-beam Kevin rigged up incorrectly doesn't fall and kill Bob. If you think "5" is a crazy amount of design factor, or that design factors sound dumb, there are plenty of construction videos on YouTube that show that people still manage to exceed the MBS on critical rigging, even with high design factors. In fact, some hoisting operations actually call for a design factor of 10!

D-ring shackles, snatch blocks, cables, and straps all have design factors built in to account for non-ideal conditions and people doing dumb things (maybe like, I don't know, in fourwheeling...?).

The first thing you should know about your winch cable is that its Working Load Limit is far below whatever you're doing with it. A 5/16" cable has a WLL of 1980 lbs and a 3/8" winch cable has a WLL of 2880 lbs.

In fourwheeling, we have no one telling us how to rig up our trucks. We take hints from the military, the hoisting industry, the tow/recovery industry, and trial and error. Winch manufacturers, in particular, aren't required to build in design factors. The closest we get to a design factor from winch manufacturers is that we should use a winch that's rated for 1.5 times our rig's trail weight.

But do you know how easy it is to exceed this "design factor"? Incredibly, ridiculously easy! Take a look at the chart below.

The actual loads on your winch cable - JEEP (4000 LBS)

In our chart we assume a trail weight for a Jeep at about 4000 lbs. This is a pretty random number, so don't use it in your calculations. Early Jeeps weigh not a lot, and later Jeeps get heavier every year. 4000 lbs is probably the weight of a fueled TJ with tools, spares, big tires, armor, bumpers, a winch, and 1-2 people.

We show ratings for 2 scenarios for 5/16" winch cable and 3/8" winch cable: single line and double line. If it's not obvious, double line simply means that the winch line runs from your winch to a snatch block, back to a recovery point on your vehicle. Ignoring all the efficiency losses that happen when you're winching in the real world, this doubled cable supports twice the weight of a single cable.

How did we calculate the loads of being stuck? We used the "mire" factor in a US Army recovery manual. They aren't perfect, but they provide us with a rule of thumb.

The actual loads on your winch cable - TOYOTA TACOMA (5500 LBS)

For our Tacoma, we are using a built double cab with a trail weight of 5500 lbs - this is passengers, camping gear, tools, spares, big tires, armor, etc. You can see that in all three of our scenarios, we break the winch cable in a single line pull. In a double line pull the winch cable is always above the rated WLL of both 5/16" and 3/8" winch cable. The chart suggests that you should always carry a snatch block and use it frequently if you're stuck with a heavy rig.

Your winch cable basically sucks

So, what did you find out? Basically, your winch cable is weak. Assuming all your other gear is properly rated, your winch cable is likely to be the weakest link in your recovery setup. If we ignore the fact that there is practically no design safety factor, we can see in the chart that it's easy to approach or exceed your winch cable's breaking strength. This is why winch cables break on the trail.

Your winch cable is likely to be the weakest link in your recovery setup.

There are tons of Jeeps running around with 8000-9000 lb winches with 5/16" cable. We can see that according to our calculations if that Jeep gets stuck to the tires, a winch line that's in perfect condition will be 1800 lbs away from snapping. That extra load could come from extra water and fuel, passengers, hidden logs in mud, and a slight uphill slope. A winch cable that's old and worn with several broken wires doesn't stand a chance in this situation. In a double line pull the 5/16" winch cable stays intact in every scenario, but in our worst scenario of being mired on a 45° slope it still comes close to the breaking point.

By the standards of the cable industry, you might be okay using a 7/16" cable on a early Jeep, FJ40, or early Toyota pickup winch. In fact, if everyone actually used cables with the correct WLL in single line pulls, cable breakages would be a thing of the past.

Winch Cable vs. Shackle, A little crazy to think about

Let's just consider another piece of fourwheeling recovery gear, the D-ring shackle. Most fourwheelers typically have some

3/4" shackles laying around. For a standard 3/4" screw pin shackle, the

Working Load Limit is 9500 lbs. The Minimum Breaking Strength

(MBS) is 57,000 lbs. There is a design factor of 6. With a 3/4" shackle the Minimum Breaking Strength is 6 times the WLL.

The Working Load Limit of a 3/4" shackle is five times the Working Load Limit of a 5/16" winch cable.

If you don't remember from above, standard 5/16" 7x19 aircraft cable has a Working Load Limit of 1960 lbs and a Minimum Breaking Strength of 9800 lbs, giving us a design factor of 5. The WLL of 5/16" winch cable is about 20% of the WLL of a 3/4" shackle. How come no one is losing their minds!?!?!?!?!?

This is just a huge incongruency in how we think about recovery safety. We've all accepted 3/4" shackles with a WLL that's close to 2X many 4x4 weights, but we've also accepted winch cables with WLLs that are 1/2 those same 4x4 weights.

What are we saying here? That you should upgrade to 9/16" cable for all your winching? No. If you calculate it out, you would lose 30-60% of the length of your winch cable by moving to a much larger wire rope size. So no thanks, it's nice having more than 50 feet of winch line.

What we are saying is that maybe you want to treat your winch cable a little better. Maybe you can keep it a little more lubricated, keep it wrapped on the spool nicely, buy it flowers once in a while instead of asking it to get all dirty for you when you haven't been taking care of its needs. Have a little more respect for it when you're using it.

How can you prevent your winch cable from breaking?

As we saw above in our charts, in perfect condition there is little margin for safety with a winch cable. We aren't telling your to swap to a bigger winch cable. You'd end up with a short winch cable, that would be difficult to use on the trail. But there are some things you can do to keep your winch cable from breaking.

Use a snatch block

A snatch block effectively doubles the power of your winch and will nearly double the strength of your rigging. It also halves the length of winch line available, but you can make this up with a winch extension strap. You have the option of doing a long distance, single line pull, or a shorter distance double line pull. In any case, it's more versatile than just having a fat, short winch cable.

Maintain your winch cable

First, keep it correctly wrapped on the drum. Remember what it looked like when you got your winch? Nice, tight, even wraps. From the factory, the winch cable probably isn't that tight, so you should spool it out and rewrap it. Spool it in with a minimum of 50-100 lbs on the line and make sure it's neat.

Second, you can lube your winch cable. Winch cable moves and generates internal friction between the movement of the strands and wires. The best way to lube it is bent around a surface like a snatch block so that the oil can penetrate the strands and wires. Use something light like new motor oil, but don't use sticky lubes like wheel grease that will trap dirt.

Third, don't keep it bent in weird positions for long periods. For example, many people like to connect their winch cable to a recovery point on the bumper and reel the winch cable in. This deforms the winch cable where it wraps around the fairlead and will weaken it in the long term.

Fourth, don't loop around an anchor and attach the winch cable to itself with the winch hook. People still do this, we just saw it happen in Kentucky. What is this, 1995? The hook damages the cable, the anchor can damage the cable, and if the anchor is a tree, it damages the tree, eco-warriors see tree damage, and public lands get shut down. Good going, Kentucky! Wrap a tree strap around your anchor, connect a shackle, and hook your winch cable to the shackle. Boom! Done.

Get out your shovel and your Hi-Lift

Don't be lazy. We know it's easier to winch out than to dig out. But sometimes you just get yourself into a pickle and you need to break out the shovel sooner rather than later. You can solve lots of problems by digging out in front of your tires, taking a different line, or jacking up a tire and stacking rocks and logs under it. If you get badly bogged in mud, you're likely to have a bad time and/or snap a winch cable if you don't do something to break the mud's suction.

Don't jerk the line

A winch line is not a recovery strap. Repeat. A winch line is not a recovery strap. Winch lines are supposed to see static loads, like pulling your rig up a hill slowly. Hooking your winch cable to another vehicle and letting that vehicle try to pull you out will break your winch cable. Cables are designed for consistent loads, not shock loads. It's easy to exceed Minimum Breaking Strength of a winch cable in a snatch recovery operation because of the large forces that are generated.

Switch to a synthetic winch rope

If you want to increase your safety factor, synthetic winch lines have higher Minimum Breaking Strengths than steel cable. Where 5/16" steel winch cable breaks at 9800 lbs, MasterPull's 5/16" standard winch rope breaks at 12,300 lbs which is an okay strength increase. Their 5/16" Superline, however, breaks at 21,700 lbs which is more than double the steel winch cable and a huge improvement in the safety factor. You can also reap large strength benefits by using a 1/16" larger winch rope that has a slightly shorter length. There is little doubt that for most fourwheelers synthetic winch line is going to be safer.

Winch Cable Characteristics - THE BORING (BUT USEFUL) STUFF

Want some technical cable information? Below is some handy information about what your winch cable actually is, what the parts are, and some specs on different wire ropes.

Cores - 3 TYPES, 2 WE CARE ABOUT

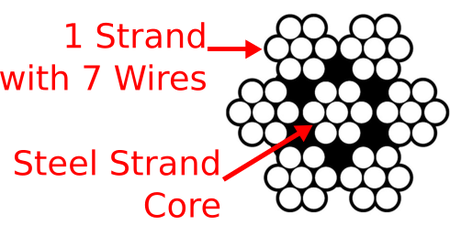

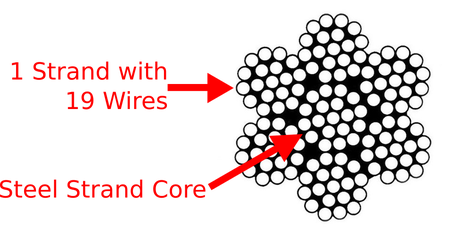

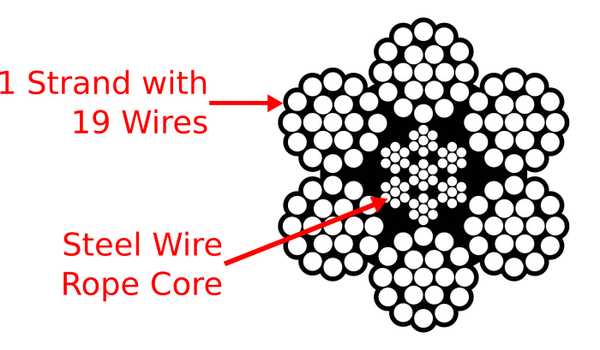

Steel cable has three parts: the core, the strands, and the wire.

The core runs through the center of the wire rope. It can be fiber or steel. If it's steel, it can be either a strand or another section of wire rope. A strand is a section made up of individual wires. A strand can exist on its own as a wire rope (like with 1x7) or be twisted with other strands to make wire rope. A wire is an individual wire that is twisted together to make a strand.

Said another way, several wires are twisted together to make a strand. A strand can be used on its own or it can be twisted with other strands to make a larger cable/wire rope.

Cables and wire ropes are named based on the strand and wire configuration. A typical configuration looks like this:

"STRANDS"x"WIRES PER STRAND" "CORE TYPE"

So if we want to describe a 6 strand fiber core wire rope with 19 wires per strand we get: 6x19 FC. Here are a few other example configurations.

Because of the large wire size, 7x7 is stronger than 7x19. However, it is also not as flexible. If you've wrangled with your winch cable, you know that making it less flexible wouldn't be ideal.

The 7x19 is a reasonable compromise between strength and flexibility and this is the most commonly used cable for 4x4 winch cables.

| Core | Strands | Wires per strand | Wires per wire rope | |

|---|---|---|---|---|

| 6x19 FC | 1 (Fiber) | 6 (Steel) | 19 (Steel) | 114 |

| 6x37 FC | 1 (Fiber) | 6 (Steel) | 37 (Steel) | 222 |

| 1x7 WSC | 1 (Steel), counted as a strand | 1 (Steel) | 7 (Steel) | 7 |

| 7x19 WSC | 1 (Steel), counted as a strand | 7 (Steel) | 19 (Steel) | 133 |

How the core, wires, and strands are configured determine three things that are important in a winch cable:

There are three types of cores for steel cables: FC, WSC, and IWRC. We only care about two but we'll describe all three. To really cut to the chase, if you need 3/8" or less, you'll be using WSC. If you need over 3/8", you'll be using IWRC.

Fiber Core (FC) - NOT FOR US

FC usually has a polypropylene core, which means that the core is NOT steel like WSC or IWRC. This is used for winching in other applications, but its breaking strength is too low for use on 4x4 winches.

Fiber core typically has less strength and more flexibility than other types of wire rope. It comes in configurations like 6x19 FC where there are 6 large primary strands made of 19 small steel wires. It also has 1 large "strand" (not a real strand) in the center made of some type of fiber that isn't steel. Cores used to be something organic, like hemp, but now are usually polypropylene. The fiber core won't resist crushing that could occur on the winch drum like a steel-cored wire rope.

Because of its decreased strength in comparison with a similar-sized steel-cored wire rope, you wouldn't use it for a 4x4 winch cable replacement.

Wire Strand Core (WSC) - FOR WINCH CABLES 3/8" AND UNDER

The 7x19 is a reasonable compromise between strength and flexibility and this is the most commonly used cable for 4x4 winch cables.

7x19 Wire Strand Core (WSC) aircraft cable is the type of winch cable you'll typically use for winch cable sized up to 3/8". Any winch that you buy for your 4x4 will use this type of cable. Why? The core is the strongest of the 3 core types due to the large wires and the strands-per-core are a good compromise between strength and flexibility. Instead of the fiber core that FC has, WSC has a strand core. This means that a single steel strand like the outer strands makes up the core. The core is a true strand and in 7x19 will be made up of 19 wires, just like the outer strands.

So, to break it down: 7x19 WSC is made up of large 7 primary strands. One strand makes up the core (giving it the name Wire Strand Core). Each of these 7 strands is made up of 19 wires twisted together.

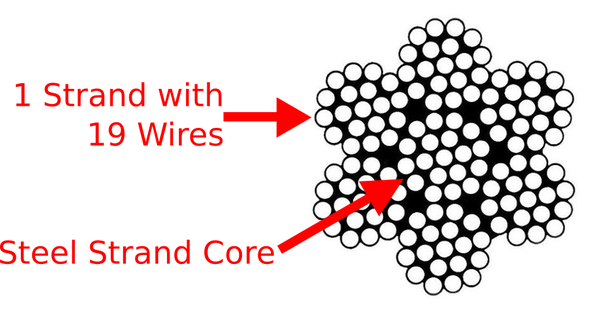

Independent Wire Rope Core (IWRC) - FOR WINCH CABLES OVER 3/8" DIAMETER

If you need a winch line larger than 3/8", you'll likely be using IWRC. There are many configurations of IWRC, so make sure you are using one that is flexible enough for a 4x4 winch drum and also has a reasonable breaking strength.

IWRC is just like WSC and FC except that the core is another wire rope. So something like 6x19 IWRC could have 6 strands with 19 wires each and a core made up of wire rope. The core usually has smaller wires than the strands and this keeps the rope more flexible than WSC and stronger and more crush-resistant than FC. Typically, if you need to buy bulk winch cable larger than 3/8", this is what you'd get.

Winch Cable Materials

This is a standard 3/8" Warn winch cable. This type of cable is 7x19 right regular lay aircraft cable with a breaking strength of 14,400 lbs.

Winch cables should be made of galvanized steel for corrosion resistance. You can buy WSC and IWRC in stainless steel, but the Minimum Breaking Strength is reduced. As we saw above, the last thing you want for your winch cable is less strength and it can be a significant difference with stainless wire rope. Wire rope is typically made out of either IPS (Improved Plow Steel) or EIPS (Extra Improved Plow Steel). EIPS is about 10% stronger than IPS, but this doesn't really translate into meaningful strength increases for when you're on the trail. For winch lines, far greater strength increases can be had by switching to synthetic winch ropes.

Putting it all together

So, if you need a new winch cable, you have two options: just buy a new one made by your winch manufacturer or buy some bulk cable and build your own.

If you want to buy bulk, for cables 3/8" and up you'll want 7x19 galvanized WCS made of IPS or EIPS. This is also known as aircraft cable. Although we may call it wire rope, winch rope, or lots of other colloquial terms, the trade name is aircraft cable. Strangely enough, it is usually labeled as not for use in aircraft. Go figure.

For wire rope over 3/8", a galvanized 6x19 IWRC will work fine. Pick one with a high breaking strength.

It's difficult to make out all 7 strands in this cable, but you can see that the wires are all the same size. There are 19 wires per strand.

Standard Winch Cable Strengths

These are cables that are typically found on 4x4 and ATV winches. As you can see, the breaking strengths are not that high and the rated WLLs are far below the typical forces that the cable will see on a normal winching day.

| Diameter | Type | Working Load Limit | Breaking Strength | Design Factor |

|---|---|---|---|---|

| 3/16" | 7x19 WSC galvanized (aircraft) | 840 | 4200 | 5 |

| 1/4" | 7x19 WSC galvanized (aircraft) | 1400 | 7000 | 5 |

| 5/16" | 7x19 WSC galvanized (aircraft) | 1960 | 9800 | 5 |

| 3/8" | 7x19 WSC galvanized (aircraft) | 2880 | 14400 | 5 |

| 7/16" | 6x19 EIPS IWRC galvanized | 4080 | 20400 | 5 |

| 1/2" | 6x19 EIPS IWRC galvanized | 4600 | 23000 | 5 |

Last updated: September 5, 2019