The 5 Best Hi Lift Jack Mounts

The Hi Lift Jack is probably one of the best tools you can take with you off road.

- It lifts you when you’re stuck

- It can winch you out of tight spots

- Helps you change tires on tall 4x4s

But you need to make sure it's securely mounted. Hi Lifts are heavy and you shouldn't let your roll around in the back of your rig.

We'll take a look at a few mounts to keep your Hi Lift jack secure and your rig tidy!

- The Best Hi Lift Jack Accessories

- Use Your Hi-Lift Jack as a Winch

- The Hi-Lift Jack Buyer's Guide

- The rubber pads go between the body and the bracket to protect your paint.

- Install one mount completely, then the other. This will keep you from having to realign your hood (this is not fun).

- If you have a Jeep and you care about it, this kit should not be your first choice. There are several Jeep-specific Hi Lift Jack mounts that you should look at before drilling holes in your sheetmetal.

- Don’t mount these brackets on plastic or hanging on thin metal. While mounting on top of a hood would be fine, mounting a hi lift to the side of your 4x4 would eventually fail. The sheetmetal of the body is not strong enough to support that type of load. Eventually the metal will fatigue, crack, and the jack will fall off. If you really needed the jack there, you’d have to weld in some reinforcement on the back of the body panel.

- Attach the brackets tightly to your jack, then mark the bracket holes. After you drill the first bracket’s holes, fit everything again and make sure your marks still line up. You don’t want to drill twice.

- The four mount holes on each bracket are 5.5” x 1.375” on center. The holes are slotted.

- Each large bracket is 6.75” long x 2.5” wide x 3.5” high.

- If you want to keep the plastic hinge covers, you have to drill them. Otherwise, this is a bolt-on mod.

- It installs with the 4 factory hinge bracket bolts.

- It will not fit a TJ without modification.

- Aftermarket bumpers besides Rugged Ridge may or may not fit.

- TM-700 fits tubing with an outside diameter of 1-2”

- TM-750 fits tubing with an outside diameter of 2-3”

- The jack studs and knob thread is 1/2”-13.

- Use some thin vinyl or rubber strips to pad between the mount brackets and your tubing to prevent scuffing and scratches.

- Use some anti-seize on the threads of the hi lift studs that the aluminum knobs spin onto. The dissimilar metals can corrode.

- If you’re installing it on a bull bar or bumper, make sure that the jack won’t block your headlights or parking lights.

- If you’re mounting the jack inside a Jeep, make sure it’s not close to anyone’s head. It’ll be closer to people’s body parts than the roll bar and it won’t be padded.

- If you’re mounting the jack inside a Jeep, make sure that you can mount and unmount the jack with the hard and soft tops in place.

- If you’re mounting the jack inside a Jeep, throw a blanket over the brackets/jacks before top removal and installation to prevent damage.

- Do not mount to tube sliders. That is a terrible place for a jack to be mounted.

- leave the padding partially unzipped

- make a short slice in the padding to let the bracket poke through - this looks much cleaner

Two good reasons for properly mounting your Hi Lift?

1) Avoiding death:

We’ve all

seen photos of Jeeps that have rolled off the trail with cooler contents

and tools scattered all over the place.

What happens if one of those flying things is your jack?

You need your jack to be secure for the safety of you, your loved ones, and others on the trail.

2) Neatness:

Hi Lifts are huge and heavy. The

length of a Hi Lift takes up a ton of room in your vehicle, especially

if you have a smaller vehicle like a Jeep.

If you need to move your jack to get to something else, the heaviness and bulkiness of the jack makes it a pain to maneuver. By mounting it on the exterior of your 4x4 you save interior space, always have it easily accessible, and never have to worry about it banging around in a rollover.

Look at These Features Before Buying

You should look for a few basic features in any Hi Lift Jack mount.

Mounting System

There are several ways to mount a hi lift jack to your 4x4. Most of

the hi lift jack mounts out there are not vehicle-specific. Common hi

lift jack mounting points are the hood, the bumper, inside a truck bed,

the roll cage, and the roof rack. Whatever location you use make sure that any Hi-Lift jack accessories also fit if you leave them permanently attached to your jack.

Lots of wheelers mount spare parts

under the body to keep them out of the way. We don’t recommend that you

try this with your Hi Lift.

If you get bogged up to your axles in mud, or you’re on a seriously rocky trail you’ll regret that you have to crawl under your truck to grab your jack. It will only be made harder by the fact that the jack is so long and unwieldy.

One issue with having your jack outside all the time is corrosion. We don’t worry too much about the foot, handle, or bar of the jack too much. However, the jack mechanism can rust. When this happens, your jack will usually go up just fine. But when you want to go down, the pins will jam from the corrosion. We always carry some spare parts and WD40 on the trail to deal with a sticky jack. We suggest using a cover and carrying some lubricant to keep the hi lift operating smoothly.

Remember that some mounts are very specific to the application. For instance, if you have a Yakima roof rack and want to mount a hi-lift to it, look for a Yakima hi-lift mount.

Locks

Some mounts lock and some don’t. Some use a knob lock and some allow

you to use a small padlock. Most knob locks from recognized brands are

very resistant to the weather and won’t be difficult to open after

they’ve been on your 4x4 for a while. Their internal components are made

of non-corroding stainless steel and aluminum.

On the other hand, if you buy a cheap padlock to secure your hi lift jack, it’ll probably rust internally making it difficult or impossible to get at your hi lift when you need it most. Instead, we recommend a corrosion resistant brass padlock like this one:

Materials and Corrosion

Mounts and hardware that are made of plain steel will eventually rust. The jack will inevitably rattle on the mount at some point, or you'll bang the mount with the jack. So, depending on your use, think about the materials and finishes in the mount.

Stainless steel and aluminum will never rust, although aluminum can eventually start to corrode if anodizing and powdercoating wear away. Powdercoating is quite durable unless it takes a very hard direct hit. Paint and plain steel are the worst combo for combating rust, but are also easy to touch up with a can of spray paint.

Hi-Lift Hood Mount for Jeep JK and Unlimited 2007-2017 - HM-800

Mounting a Hi-Lift Jack on your hood keeps it out of the way, but it may slightly block your view out of the windshield.

Add a Hi Lift Jack to your Jeep JK so you can go further without

fear! This hi lift jack mount for 2007-2017 Jeep JKs and Unlimiteds is

machined from lightweight and strong 6061-T6 aluminum. It mounts

directly to the holes in your Jeep’s hood. This is a no-drilling

installation!

The aluminum brackets are anodized black and the included

hardware is stainless, so you don’t need to worry about corrosion.

By mounting the jack on the hood, it’s out of the way but easily accessible if you need it. The included plastic knobs are easy to use with gloved hands. They don’t lock, but you can buy one or two locking knobs and add them later if you need them.

The machined aluminum and stainless steel parts will never rust, and they look good, too.

This kit does have some small issues. The recommended configuration

of the jack is with the handle toward the windshield. Some Jeeps have no

problems with this, but in others this may cause the jack to interfere

with the windshield washer sprayers. Instead of a clean spray pattern,

the sprayers will just hit the jack.

If you try to flip the jack over, the sprayers work a little better. But in this position, will dimple your hood a tiny bit. It sticks out just enough to do some damage. The solution is keep the handle towards the hood and install a sprayer relocation kit. They are fairly inexpensive and should take less than 30 minutes to install.

Getting the jack off the hood to use it might make you nervous. If you think you can’t get your jack off your hood without scraping or dinging it, lay down a towel to protect your paint.

You won’t be able to flip your hood all the way back to the windshield. To do that, you’ll need to unbolt the jack first, then you can flip your hood all the way back. You can still open the hood and use the prop with the jack attached.

Lastly, the more vertically-challenged among us might find that the jacks blocks their view out of the windshield. If you’re around 5’ tall or less, you may want to look at another mounting point that isn’t on the hood.

Installation Tips

Hi-Lift Jack Mount 4XRAC 4x400 - Universal

This is a decent universal mount, but this is a terrible mounting location for fourwheeling!

This universal Hi Lift jack mount will mount anywhere you can fit your jack. It’s a good strong mount, but it’s not corrosion-resistant and we don’t like the jack mounting system as much as some higher-end units.

The brackets are made from 1/8” thick steel and have two holes in each bracket. The brackets are painted black and the included hardware is galvanized steel. The brackets can be set at virtually any distance apart on the jack, just as long as they each line up with a hole in the bar. This mount does not come with a lock, but it is lockable. Two carriage bolts mount the jack to the brackets, then a wingnut tightens against the bar of the jack. In the end of each carriage bolt is a hole that will fit a 1/4” lock.

This hi lift jack mount is plenty strong, but it won’t be as corrosion-resistant as a mount with aluminum and stainless steel components. If you don’t have a handle keeper, this comes with a velcro strap to hold your jack handle in place.

While this is a super-simple universal Hi-Lift Jack mounting system, the components are all made of plain steel, which will eventually rust. Also, there are no big, fancy knobs that make it way easier to get the jack on and off in the mud or cold.

One annoying thing about this mount is the way the jack mounts. The carriage bolts that hold the jack aren’t fixed in any way. After getting the jack lined up with the carriage bolt, you still have to line up the outer bracket, then you have to spin on the wingnut. If you’re dismounting your jack frequently this could get old really fast. It would make thing a little easier if the carriage bolts were welded to the brackets so that they would stay in position as you mounted the jack.

In the first image of this mount above, imagine that Jeep is stuck in a mudhole. To remove the jack you need to keep track of a lock (maybe), two wingnuts, two small brackets, and 2 carriage bolts. If you’ve ever actually been stuck in mudhole you know that fiddling around with little parts can be extremely tedious.

A few installation tips:

Rugged Ridge Hi Lift Jack Mount for 2007-2017 JK Jeeps - 11586.01

The Rugged Ridge Hi-Lift Mount is out of the way, but still very easy to access. It won't block the view like a hood-mounted jack.

This Jeep Hi Lift Jack mount attaches to the stock spare tire holder on 2007-2017 Jeep Wrangler JKs. We like the placement because it puts the jack out of the way. Compared to a hood mount, this won’t block your view out the windshield, it won’t block your washer nozzles, and it’s easier to put on and take off without worrying about your paint. It comes with a wrinkled black powdercoat finish. Powdercoat is hard, so unless you chip it, the finish should hold up a long time.

We really like how it mounts. The weight of the jack rests on the bracket, so the bolts that hold the jack in place only hold it in place - they don’t experience any shear forces as they would if the jack hung from the bolts in this position. There are two knobs that can be operated with gloved hands for securing the jack, but neither knob has a lock. There is a cutout for a lock, so its easy to stick on a padlock when you need to.

This mount is compatible with stock and most aftermarket bumpers as long as they don’t have a tire carrier. It is definitely compatible with the Rugged Ridge XHD rear bumper with or without a tire carrier.

A 48” jack will stick up above the the roofline on your JK by a few inches. If you’re an East Coast or PNW wheeler where trails are tight, you might have an issue with branches catching on the jack. There isn’t really a way to mitigate this unless you cut your jack down. On the other hand, this usually isn’t a problem on established trails, and you might already be rocking a tree-snagging roof rack.

This mount bolts on quickly. If you want to keep the stock plastic hinge covers, you'll have to drill them.

What size tires will fit next to the jack?

You can easily fit a 35” tire next to the jack. Rugged Ridge says that you can fit up to a 37” with some small modifications. Let’s just note that that is more weight than the carrier is rated for (50 lbs), but also that the carrier comes overloaded from the factory. Most people are reporting no issues with larger tires, but you’ll want to make sure that your tire carrier hardware is always in excellent shape. Upgrade your hinge or use a different mount if you’re off roading a lot and you have large tires.

Installation Tips

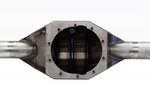

Hi-Lift Jack Tube Mount - TM-700/TM-750

The machined aluminum knobs are big enough for gloves and will never rust.

If you have free tube on your 4x4, this is a great, clean-looking

mount! With this kit you can mount to roll bars, rollcages, bull bars,

roof racks, and tube bumpers.

The brackets and knobs are machined from

6061-T6 aluminum. The u-bolts, nuts, washers, and Hi Lift mounting studs

are all stainless steel.

This kit should be virtually corrosion-free,

although we always like to put a little anti-seize on all dissimilar

metals. The knobs are large enough to operate with gloved hands.

This hi lift mount will work with any Hi Lift or farm jack that can fit the jack mount studs. The studs are 1/2” diameter so that means that your jack bar holes need to take at least a 1/2” bolt. There is no strap or plastic handle retainer to hold the jack handle in place, so you either need to buy or make one to keep your jack handle from rattling. The kit attaches to two tubing sizes:

The smaller kit (TM-700) is great for bull bars and roof racks that have smaller diameter tubing. If you do have a roof rack, check that your manufacturer doesn’t already make a Hi Lift jack mount. If they do, it might fit a little better and look a little cleaner.

The larger kit (TM-750) is great for larger tubing on roll bars, rollcages, and tube bumpers. It will fit roll bars on CJ/YJ/TJ/JK Jeeps with the padding removed. Some people report a tight fit with later roll bars that have plastic pieces.

This mount is held in place with friction. You tighten the nuts on the u-bolts to clamp the mounts to your tubing. You want this to be tight and secure. On bumpers and cages, the tube will likely be thick enough not to kink. On roof racks and any tube with thinner metal, be a little more cautious that you don’t crush or kink the tube while tightening. Kinked and crushed tubing can become a failure point. On a roof rack this is not a huge deal, but a kink in your roll cage will compromise it.

This is an easy way to mount your Hi-Lift Jack if you have some free tube.

We don’t recommend this mount if you’re really concerned with theft. First of all, the knobs don’t lock. If you’re not too concerned, you could buy a locking knob and call it a day. More importantly, the u-bolt nuts are easy to remove with a wrench. You could secure the jack with a cable lock or u-lock but it would not be as clean. You could buy a locking knob and tack weld the nuts to the u-bolts, but welds make it very difficult to move or remove the mount in the future.

The stainless hardware and machined aluminum Hi-Lift Jack brackets mean that you'll never have streaky rust stains.

Installation Tips

Dominion OffRoad Jeep JK Wrangler 4-Door 48” Hi-Lift Jack Mount

This clean mount makes it easy to keep your tools away from thieves and weather when you have a top on.

This is a slick way to mount your Hi Lift jack plus two accessories,

like an axe and shovel. If you need an interior Hi-Lift Jack mount, you can’t get

much better than this.

This is a super-stealthy way to keep your jack

out of the weather and the jack plus tools take up dead space in your

Jeep. You store the jack inside, suspended from the rear of the roll

bar. Dominion OffRoad currently makes this only for the 4 door

JK, but they say they have a 2 door model coming out.

This is made to fit only a 48” hi lift or farm jack on it. If your jack is longer or shorter it will not fit. The brackets are steel, painted black. The hardware is black zinc-coated for corrosion resistance.

How it works

In this system, there are 4 brackets. Two brackets bolt to the roll bar behind the rear seats and each end of the jack is, in turn, bolted to the brackets. Note that the jack is part of the mount. The other two brackets secure to the hi lift with wing nuts. These brackets have quick fists that’ll secure an axe, shovel, or other appropriate-sized tool.

This is the "unzip padding" installation method.

This is the "slit in the padding" installation method.

When mounting the brackets to the roll bar you have two options with the padding:

This kit works with hard tops, soft tops, and bikini tops. One issue is that when putting the soft top up or down, it won’t clear the jack, which means the jack needs to come off. This could be a bad thing if you have bad weather come up quickly.

You can lock the jack with a padlock, but theft shouldn’t be much of a problem since this is inside your Jeep. If a thief is going to steal your Hi Lift off this mount, you’ve got bigger problems because he’s already in your Jeep.

The mount tucks close to your roof and out of the way.

The positioning of the jack and tools is great. Your rear view is not blocked, you’re not cluttering up the outside of your Jeep, and you don’t have to worry about corrosion on the mechanism of your jack.

There are some downsides to the mount: To use your jack, you have to remove the tools and unbolt the hi lift from the mounting brackets. This is a pain, but it’s worth it if you don’t anticipate constantly removing your jack. Additionally, if your Jeep is jam-packed for an off road trip and you need the jack, you’ll need to maneuver the jack from inside to outside, and a 48” Hi Lift jack can be a little unwieldy. For most people, having the jack away from weather and theft, and out of the way, will be worth it.

Last updated: September 5, 2019