3 Jeep XJ Frame Stiffeners to Keep Your Cherokee From Tearing Itself Apart

Jeep XJs tick a lot of the boxes we want in an off road rig: They're light, cheap, have room for gear, and are pretty cheap to build.

But:

There are some drawbacks to building your XJ.

One of the biggest is the unibody frame. It might be okay on small tires with no lift, but as soon as you put a lift kit and big meats on your XJ, you're XJ'll start flexing, creaking, and groaning.

A little flex is okay, but too much will start tearing your rig apart.

Fortunately, you can fix your unibody's flex! A set of XJ frame stiffeners will firm everything up and can even act as armor for certain sections of your body.

In this article we'll take a look at some popular, easy ways to add frame stiffeners to your XJ.

- Jeep XJ Steering Upgrades: Beef Up Your Cherokee

- Solid places to mount rock sliders, suspension mounts, transfer case mounts, and skid plates: Instead of the paper thin unibody.

- Reinforces weak steering box mount: Stock frame isn't sleeved and the aluminum spacer gets destroyed quickly.

- Prevents dents to unibody frame: Dents in the frame's sheetmetal significantly weaken the frame's structure.

- Better steering: Frame doesn't flex when you turn the wheel - no more sloppy steering.

- Rock protection: Thicker XJ frame stiffeners can be smashed on rocks without worrying.

- Get your XJ as level as possible: You don't want to have any twist or flex in the unibody or it'll be permanent after welding.

- Pull off the brake and fuel hardlines: They'll be reattached to the stiffeners.

- Mark all the areas that'll be welded with a paint pen: Clear marking and layout is why some people's stuff looks so good.

- Sand the undercoat down to bare metal: Do this in the marked weld areas.

- Use an 80 grit (or less) sanding disc, not a grinding wheel: You don't want to remove any metal from the unibody frame where you'll be welding. The frame is thin enough already.

- Weld for 1-2"

- Leave 2-3" gap

- Weld for 1-2"

- Leave 2-3" gap

- And so on...

- Practice! Get some sheetmetal and some 3/16" plate and practice some upside down lap welds. This will show you your weaknesses and you'll be able to figure out how to adjust your body and arm position to get clean welds.

- Smaller MIG wire like 0.025" will be easier to weld with.

- When you're welding, aim more at the thick frame stiffener and less at the thin XJ unibody: The weld puddle will wash into the unibody.

- Keep the torch moving! If you linger in one spot, you'll blow a hole in the unibody.

- Switch back and forth between sides to let things cool: You can weld your XJ stiffeners too quickly, but not too slowly.

- 1/8"-3/16" thickness

- Holes drilled and slots cut for rosette and slot welds

- Pre-bent for easy fitting

- Factory holes not covered up

- Front XJ frame stiffener: 1/8" thick

- Center XJ frame stiffener: 3/16" thick

- Rear XJ frame stiffenener: 1/8" thick

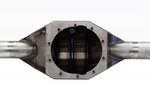

This shows how much coverage a typical front stiffener has on your Jeep XJ's frame.

If you're just looking for a good set of stiffeners you can get a popular and beefy set of center stiffeners from RuffStuff that will take a beating. Their front stiffeners will firm up your frontend and improve your steering box mount.

The Jeep Cherokee XJ has been around since 1984 and is popular for being an ultra-cheap 4x4 that you can load with gear and still be comfortable. But it has a unibody.

Here's the deal:

Unibodies are pretty common now, but the Jeep Cherokee XJ was one of the first 4x4s to use it. It took a loooong time for the XJ to be really embraced by the off road community, partly because the unibody wasn't something you found on "real" 4x4s.

But now, you can pick up XJs all day long on Craigslist for cheap, spare parts are all over, and there is a huge aftermarket of Jeep XJ-specific parts.

However:

It still has that unibody!

The unibody is the XJ's weakness and without making it stronger, you'll flex the body, snap welds, get cracks, and end up mounting important stuff to thin unibody rails.

The long slot welds distribute force and stress and keep your Cherokee's unibody frame tight to the stiffener.

Sooner or later, the stock unibody will give up. If you're running

33" or larger tires, you need to seriously think about stiffening up

your frame.

And it won't happen gradually:

One day you'll have an intact frame, and the next you'll have a bunch of little cracks that just get bigger. People that don't plate their XJ's frame often wish they had done it sooner.

XJ's without frame stiffeners live on borrowed time.

If you're building a Jeep XJ, you should start by welding on some

frame stiffeners. The stiffeners will provide a strong foundation that

you can use to mount all the good stuff: suspension mounts, skidplates,

drivetrain mounts, and sliders.

Do you really want to hang your 4 link mounts off 16 gauge sheetmetal?

How Frame Stiffeners Make Your Jeep XJ Better

The stiffeners you buy should be pre-drilled both for rosette welds and access to the factory frame holes.

After welding on some stiffeners, the first thing that you'll notice with your Jeep, especially off road, is that it handles better. Instead of feeling "loose", it'll feel tight.

Know how it feels to drive with a death wobble or an underinflated tire?

And then what it feels like to fix either one of those?

It's kind of like that. Your general driving experience goes from sucky to fun.

You'll also hear a difference when you're cruising down the trail. All the noises and creaks your XJ normally makes will stop. The unibody won't be shifting around anymore and the frame stiffeners will hold everything in place.

There are serious performance improvements that you can make with frame stiffener plates:

So what's the install like?

Installing frame stiffeners is going to take you some time. If you want the job to look clean and go smoothly, it's all about the prep work.

Prep is everything

Hold the stiffeners in place with bottle jacks and jack stands to fit them to your Jeep Cherokee's frame. You'll need to do this for marking and welding.

There are some key points to the prep work:

Also do this stuff

Pick a stitch weld pattern and stick to it. You'll want to do something like:

This does a few things for you:

First, it cuts down on welding time - there's a lot of welding involved to get these on. Second, it keeps you from overheating the frame stiffeners and unibody frame if you're welding it all in a short period of time. You really want to make sure that you're aren't putting too much heat into everything.

When you're done, we recommend sealing the unwelded sections with a flexible 3M body sealant and then slapping some paint on everything.

Can you fully weld your frame stiffeners?

Leave the full welds to the pros and race teams.

It's probably fine to do so, but if you're a booger welder and you

consistently overheat your unibody frame, you'll just make it weaker.

You're going to be welding "out of position", upside down, maybe on your

back, for a long period of time. It is uncomfortable and tiring,

especially if you're not used to it.

Stitch welding is like hedging your bets a little so that you don't get fatigued and sloppy and make a huge, brittle Heat Affected Zone down the length of your unibody.

A few welding tips

RuffStuff's front stiffeners come in 3 pieces per side to make them easier to install. The reinforcement plates fishmouth together where they meet.

XJ frame stiffeners are thick, usually 1/8" to 3/16" steel. The XJ unibody is thin - around 16 gauge or 1/16" thick.

This makes welding difficult:

It's easy to screw up when welding thick metal to thin metal because the thick metal requires more heat to melt than the thin metal. You don't want to blow holes through your frame while welding on your stiffeners because it kind of defeats the purpose of stiffening up the unibody in the first place.

So, a few tips:

Just to reiterate one point:

You need to do a few test pieces so that you can dial in your welder's settings and figure out the proper technique for welding the thick XJ stiffeners to the thin XJ frame. If you can get your technique down you won't overheat your frame and everything will look better.

For some more great unibody welding tips, check here.

3 Jeep XJ Frame Stiffeners

You can just see on the right where the center stiffeners ties in under the front stiffener.

What do the best XJ frame stiffeners look like? We like to see:

You can make your own frame stiffeners for your XJ, but it's a ton of work. If you'd rather be wheelin' you're better off buying a frame stiffening kit that's laser-cut and pre-bent to fit your Jeep.

Kits are pretty cheap for what you get and will easily save you a couple days just cutting and fitting plate.

If you're going to be pounding your rig's underside on rocks, thicker stiffeners are better. 3/16" can take a lot more rock abuse than 1/8".

RuffStuff XJ Frame Stiffener - Center

These 3/16" center stiffeners extend into the front and rear wheelwells and also protrude 1" under your floor for extra strength. This is more than other stiffeners.

The RuffStuff Specialties XJ center frame stiffener is probably one of the most well-known reinforcements for XJ frames.

Once welded to your framerails, they'll add about 45 pounds to your XJ. They're 3/16" thick - unless you have a good reason, you shouldn't go thinner than this on the center framerails since they're so exposed from below.

They are prebent, predrilled, and slotted to allow for perfect fitting on your frame. There are several holes for putting in rosette welds to keep the stiffener solid with your frame when the going gets tough.

These stiffeners have a little more reinforcement and protrusion than other stiffeners - they extend 1" under the floor and extend into both wheelwells.

If you're only going to add one stiffener set, this is the one to use.

RuffStuff XJ Frame Stiffener - Front

These 3/16" thick stiffeners come in 3 sections for easy welding. and have some nice slots and fishmouths to ensure that you're laying down enough weld.

Got sloppy steering? Steering box mount messed up?

If your steering and frame aren't damaged yet, it will be.

After you weld these laser-cut stiffeners on the front unibody of your XJ, they'll strengthen and stiffen your whole frontend and help keep your steering box in one spot!

They are 3/16" thick, which is plenty to mount whatever your want, wherever you want it. They come in 3 separate pieces for each side to minimize the amount of disassembly you have to do for installation.

Instead of holes for rosette welds, these have long slots cut in them. Welding these up will distribute stresses over wider areas and hold more of the stiffener tight against the XJ's unibody frame.

Front end stiffeners are highly recommended by anyone that's doing hard wheeling - you need to do steering box reinforcement anyway, so why not go the whole way?

Iron Rock Off Road XJ Frame Stiffener - Full

This set of Cherokee frame stiffeners starts at the front and goes all the way to the back. They are made of 1/8" and 3/16" thick steel.

Need the whole enchilada?

The Iron Rock Off Road XJ Stiffener kit is a full set, that does your unibody frame from front to rear. As you can see, it's a whole lot of welding!

This kit comes with 3 basic parts:

The whole set will add about 80 pounds to your XJ. Every weld-on panel has holes for rosette welds.

Last updated: September 5, 2019