5 Ways to Upgrade Toyota Knuckle Studs

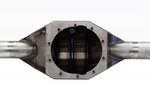

Aaaaaaaawwwww yissssssssssssssss six studs!

We can all agree with one thing:

Toyota steering studs have problems with loosening and shearing when wheeling hard and with heavy rigs.

How can you prevent broken knuckle studs? Here's the deal:

You can do this on the cheap with a $5 mod, spend several hundred dollars to replace your knuckles, or use some stronger studs.

In this article, we'll take a look at 5 ways to increase the strength of your Toyota studs, what parts you need, and roughly what's involved.

- How to Properly Install and Maintain Toyota Steering Arm Knuckle Studs

- 4 Ways to Adapt Toyota IFS Steering to Toyota High Steer

- 8 Dana 44 Studs

- 8 Dana 44 Cone Washers

- 8 Dana 44 Stud Nuts

- Drill press or mill

- 33/64” reamer or drill bit

- 9/16”-18 tap

- Taper to cut D44 taper in steering arms

- steel block or plate with a 1/2” hole

- 1/2”-20 grade 8 bolt, nut, and washer

- knuckle with a flat spot for the angle to rest

- welder

- No shims method #1: Weld the tab to the arm with both pieces installed but neither one shimmed. When assembling the knuckle, the steering arm is set up, shimmed, and the four stock bolts are torqued. THEN you tighten the fifth stud nut. With a 3/8” tab you’ll probably have a little give so that you don’t have to worry about shims.

- No shims method #2: Install all parts with correct shims and weld everything up. No shims are used on fifth stud.

- Shims method: Weld the tab to the arm with both pieces installed but neither one shimmed. Remove arm and shim fifth stud and steering arm with the same amount of shims.

- A wheel stud and lug nut

- A Dana 44 stud and cone washer

- A Toyota stud and cone washer

- Five Dana 44 studs and cone washers

- Mount the stud or bolt in a different location (often forward on the knuckle)

- Pre-threaded steel blocks from 4x4Labs

- Knuckles with appropriate material ground away

- 6-stud Toyota steering arms

- 6-stud knuckle shims

- 4 extra sets of studs/cone washers/nuts

- Welder

- They have thicker castings than stock.

- They have larger gussets than stock.

- Both sides are interchangeable.

- Trail-Gear’s Six Shooter steering arms have an extra coarse-thread hole. They include a bolt that you thread into the hole to help pop the arms off when you need to strip your axle down.

- The only high steer for FJ80s.

- Steering arm hardware is 4 Dana 60 studs and 2 1/2" cap screws per knuckle - way stronger than anything stock.

- Custom knuckle castings are thicker than stock and reinforced in key areas.

- Shimless preload adjustment with set screws - no more shims!

Why Do They Shear?

Steering studs don’t shear just because they’re weak - it’s also you,

fine reader!!! You gotta do maintenance on your studs before big

wheeling trips. The problem is that fourwheeling will loosen up the

knuckle studs. We’re not sure how this works exactly, but we do know

that if you ran the Rubicon 10 times in a row in your Mini on 37s, you’d

have loose steering studs. Instead of your studs creating a clamping force from the steering arm to the knuckle, now they have to deal with a large shearing

force. Your steering is not designed for this, so what happens? Your

studs shear and/or your knuckle cracks. “Oh,” you say, “I only have

31s.” It doesn’t matter. Small tires can still snap your studs. Big

tires will just snap them more quickly. Proper installation and torque so important so make sure you read our tips!

There are lots of heated discussions on the Internet about whether you should upgrade your Toyota’s knuckle studs (Like, settle down already guys…). We’ll say this: If you wheel a lot, you should pick a minimum of one of the “Proven Knuckle Stud Upgrades” below and do it. You’ll get a tremendous amount of peace of mind and can start worrying about the next weak part on your axle. If you’re absolutely broke, do the 5th Stud Mod. It should cost under 5 bucks.

What About New Stock Studs?

These studs were upgraded by Toyota with an E12 Torx head. However, they are no stronger than your original stock studs. They can last a long time if they are kept properly torqued.

You can buy new studs, cone washers, and nuts from Toyota and several aftermarket sources. Factory replacement studs are no stronger than stock, but they may be better than your old, beaten hardware, especially if you’ve run with the nuts loose. They usually have an E12 Torx head that makes installation and removal easier. The stock studs are 12mm-1.25M on one side and 12mm-1.5M on the other. We’ll discuss upgraded studs below. Plenty of people run on stock studs, but you must keep them properly torqued.

Breaking Studs With Hydro Steering?

If you’re running hydro steering and breaking studs or steering arm pins start with adjusting your ram. Your axle’s steering stops should not function as the steering stops - you should be limiting your steering with the ram. Why? When your knuckle contacts a steering stop the knuckle stops. A ram with too much travel continues to push on the steering arm, and it does this with much more force than the stock power steering. Assuming that the steering arm doesn’t bend, the force will stress the body of the knuckle, the steering arm, and the studs, which may cause something to break. All you need for this are spacers (steel tubing would be fine) in the ram that will limit the stroke.

Five Proven Toyota Knuckle Stud Upgrades

Some wheelers will tell you that they’ve never broken a steering arm stud while running their 38” Swampers for the last 10 years. This is entirely possible if the driver is gentle and the steering arm stud torque is meticulously maintained. However, most Toyota owners see the need to upgrade their studs since broken steering studs can seriously mess up your day. There are several methods now that you can use to upgrade your studs. Note that we are almost always talking about upgrading the upper studs where the steering arms mount. Stock studs, properly torqued, are fine for the lower knuckle studs.

We suspect a major difference between the different strengthening options is related to maintenance. For a given truck, you probably won’t have to torque the nuts as frequently when you have Dana 44 studs or a 6 stud knuckle. We still recommend regularly checking your studs until you find out how often they are loose.

When you install stud parts and steering arms, all mating surfaces must be clean and dry of oil, grease, and paint.

Paint on your cone washer surfaces or in the steering arm taper is a

recipe for loosening. The only exception is Loctite: Use high strength red Loctite on the

knuckle threads.

For the stud nuts, we used to recommend high strength red Loctite if you have chromo Birfields or medium strength blue Loctite if you have stock Birfields. This was so that when you snapped a stocker (more likely) it would be easier to pull off the steering arm to get at the broken Birfield. Now, we're leaning towards using anti-seize on the stud nuts. Why? Because you should re-torque your stud nuts before every tough trail ride and plain anti-seize will make it easier. If you have smaller tires, wheel easier trails, and generally put less stress on your Toy, high or medium strength threadlocker are fine.

Here are the options:

1) Upgraded Studs: Bolt-In Strength

Replace your steering arm studs with much higher tensile strength studs. This is a bolt-in solution.

All of the below studs are longer than stock. Why? They can accommodate steering arms with slightly shallow cone washer tapers so that you have full thread engagement between your Toy’s studs and nuts. As a matter of fact, the cone washer taper in most aftermarket arms is much further away from the knuckle mounting surface than in stock arms. If you use stock studs, make sure you have full thread engagement on your knuckle stud nuts

Our Pick: Front Range Off Road ARP Studs and Nuts

This kit includes 8 hardened Toyota knuckle studs and 8 hardened nuts to beef the attachment of your steering arms. The studs are 1/8" longer than stock.

The Toyota knuckle studs and nuts from Front Range are manufactured by ARP and have a 24,967 psi shear strength. This is the only kit where the nut hardening matches the hardness of the studs. As a result, they take the highest fastening torque of any stud upgrades which will keep them tighter longer. The studs are 1/8" longer than stock Toyota studs to accommodate steering arms with shallow stud tapers. The kit includes 8 studs, 8 nuts, and a tube of red Loctite.

Front Range Knuckle Stud Installation

Use the included high strength red Loctite on the knuckle threads of the stud and snug it into the knuckle. If you need a number, 20 ft-lbs of torque should be sufficient. To secure the steering arm, torque the knuckle stud nut to 110-120 ft-lbs. You can read this info directly from Brian Ellinger, owner of Front Range, right here.

Runner Up #1: Trail Gear Toyota Super Metal Knuckle Studs

These studs are 1/4" longer than stock and exceed Class 12.9 specs for hardware.

The Super Metal Studs are sold individually or in a kit. The individual studs come with a single, bare stud - no nut, washer, or cone washer. The studs are 1/4" longer than stock Toyota studs to accommodate steering arms with shallow stud tapers. They have an 8mm hex head to make it easier to install or remove them. Trail Gear says they are stronger than Class 12.9 hardware.

The Super Metal Knuckle Stud Kit is intended to be used for one Six Shooter Knuckle. They come with 10 studs, 10 flat washers, 10 nuts, and 6 cone washers. You could use this kit to do two standard 4-stud Toyota knuckles if you didn't need all new cone washers.

Frankly, this kit is perfect for fitting out a Six Shooter Knuckle - since the Six Shooter has 2 extra studs, stud strength shouldn't be as much of an issue as it is with standard 4-stud Toyota knuckles.

This kit is designed as a hardware set for one Trail Gear Six Shooter Knuckle, but you can use it to outfit your stock 4-stud knuckles if you don't need all the cone washers.

Trail Gear Super Metal Knuckle Stud Installation

Use high strength red Loctite on the knuckle threads of the stud and snug

it into the knuckle. If you need a number, 20 ft-lbs of torque should

be sufficient. To secure the steering arm, torque the knuckle stud nut

to 75-80 ft-lbs.

Runner Up #2: Trail Gear Toyota Magnum Knuckle Studs

This is Trail Gear's strongest stud for Toyota knuckles. It's made by ARP and is 1/4" longer than stock.

The Toyota Magnum Knuckle Studs are Trail Gear's strongest studs, but they are also the most expensive. Like the Front Range studs, they are also manufactured by ARP. They are only available as single studs and do not include hardened nuts or other hardware. Since they don't include hardened nuts, they take a lower torque than the Front Range ARP studs. The studs are 1/4" longer than stock Toyota studs to accommodate steering arms with shallow stud tapers. They have an 8mm hex head to make it easier to install or remove them.

Trail Gear Toyota Magnum Knuckle Stud Installation

Use high strength red Loctite on the knuckle threads of the stud and snug

it into the knuckle. If you need a number, 20 ft-lbs of torque should

be sufficient. To secure the steering arm, torque the knuckle stud nut

to 80-100 ft-lbs.

2) Install Dana 44 Steering Studs

This is quite a bit more work than the ARP studs. Stock Dana 44 steering arm studs are 9/16”-18 and have a shear strength of 22,354.1 psi (stock D44 is weaker than the 12mm ARP). For comparison, 12mm studs are 0.472” in diameter; 9/16” D44 studs are 0.562” in diameter. 8 stock Dana 44 stud kits will run around $65. However, 8 Dana 44 ARP stud kits run about $90, giving you the option for even more strength.

Parts:

Typical stuff needed for this:

BUT…

But the devil is in the details. You need to drill and tap each hole in the knuckle for 9/16”-18. All of this work needs to be square. You should use a 33/64” reamer or drill bit to size the hole, then tap the holes with a 9/16”-18 tap. This is not for the faint of heart. Check our sources at the bottom for some great info on techniques. Your steering arms also need to accommodate the Dana 44 stud and cone washer taper. Which means that you need to get your existing arms machined or get some made-to-order arms.

Dana 44 studs are much bigger than stock Toyota studs, but require taper machining in the steering arms and drilling/tapping stud holes in the knuckle. This work must be perfectly straight.

| Dana 44 steering arm stud | GM 3965137 |

| Dana 44 steering arm cone washer | GM 3965138 |

| Dana 44 steering arm stud nut | GM 9442950 |

| Dana 44 steering arm ARP stud kit | D44116K |

Frankly, we have a little trouble recommending the Dana 44 studs because of the amount of precision work they require, but they are clearly a strong option. Keep reading....

3) Upgrade your existing knuckles to five-studs: The Fifth Stud Mod

Nut is inside the knuckle and the tab is gusseted.

This is a great cheap trick for increasing your studs’ resistance to

shear forces. Bobby Long (of Longfield fame) came up with the five

stud several years ago. A chunk of steel is welded to the outside of

the steering arm. A bolt is run from the inside of the knuckle through

the tab you just welded on. That’s it. Neither the knuckle or the steering arm is cast iron, so it's fine to weld to either one.

Parts:

Typical parts needed for this are:

Little details

Make sure that the arms you’re using are not cast - most aftermarket arms aren’t, but cast arms have been sold in the past.

You need to make a flat spot on the knuckle for the tab to rest on - some people machine this, some just grind it in and call it good.

The fifth stud needs to be parallel to the other studs. If you have 5 studs sticking up, and one of them sticks out at an angle, you won’t be able to remove or install your steering arms.

Drilling for the 5th stud mod. Note that the drill bit is perpendicular to the steering arm surface.

A nut or a bolt?

Most people use a bolt welded to the inside of the knuckle that protrudes from the knuckle up into the steering arm, instead of a nut welded to the inside of the knuckle.

However, Bobby Long advocated for welding a nut to the inside of the knuckle

instead of a bolt. Why? The inside of the knuckle is not parallel to

the steering arm mount surface, so he thought it was easier to assemble

everything, then tack weld a nut to the inside of the of knuckle. If

you use this method, make sure that your bolt doesn’t protrude to far

into the knuckle. We think most people ought to have around 1/2” of

clearance inside the knuckle, but this may vary. Remember also that

later Birfield bells have a larger bell OD than earlier Birfs and chromo

Birfield bells have an even larger bell OD.

The head of the bolt (or nut) is welded to the inside of the knuckle between the two nubs since there isn’t enough material to run threads.

How do you shim the new tab?

Shims! In theory, it would seem that you would need to shim your new steering arm mounting point. Some do and some don’t. Here’s how people do it:

In theory, with one set of steering arms, one set of knuckles, and one set of bearings, you could set your shims once and never need to do it again. However, if you have any variance in that combo in the future, you may need to change your shims.

There are lots of variations on this method.

There are a few variations to the Toyota 5th stud mod. In no particular order they are:

Almost all of the above variations use tapered fasteners which will result in higher clamping force as well as resisting shear forces. However, we suspect this is overkill, especially because this is supposed to be a cheap/easy trick and because of the additional machining it requires. To reap all the benefits of tapered fasteners, you’d need to machine the knuckle mount flat, install shims under the tab to match the steering arm, and machine a taper into the tab coming off the steering arm to fit the lug nut or cone washer. All the parts need to fit together properly (perfectly flat) in order to see all the benefits of using a tapered fastener.

Lastly, a great combo for many wheelers is ARP studs plus the fifth stud mod. This is both strong and affordable.

4) Upgrade your existing large pattern knuckles to six-studs

These weld-on blocks by 4x4 Labs require you to grind and weld on your knuckle. Toyota knuckles are cast steel, so this is not a problem.

You thought we’d go straight to the aftermarket 6 stud knuckles right? Wrong! With a kit from 4x4 Labs

4x4 Labs Six Stud Blocks for Large Pattern Toyota Knuckles

, you can add two studs to your big pattern knuckle and run 6 stud arms.Parts

For this setup you need:

You simply remove some material from your knuckles, fit your 6-stud arms with the pre-threaded blocks, and weld on the blocks. Stock studs are strong enough for this setup. With this configuration, you can run 6 stud steering arms from 4x4Labs or any other 6 stud arm manufacturer. Assuming you’re already buying arms, this is a great balance between the inexpensive DIY 5th-stud mod and full six stud knuckles.

One of the benefits of this setup is that it is dead simple to put together. In contrast, the fifth stud mod may take a little more head scratching. While shimming is a minor issue with the fifth stud mod, you can essentially shim as normal with this mod. We really like this 6-stud conversion since you can keep your existing knuckles and get a very significant strength increase.

The downsides are: you need to be able to confidently weld to your knuckle and you need to be precise in fitting the new stud pad.

5) Upgrade to 1 Piece Six Stud Knuckles

Finally, we come to the strongest option for preventing broken steering arm studs and knuckles: six stud one-piece knuckles. If you don’t want to worry about your knuckles and studs, you should

just buy these and be done with it. These consist of brand new, fully

cast knuckles that have provisions for six studs. This is a bolt-on

swap - no machining, welding, or drilling required.

For Toyota mini trucks, FJ40s, FJ55s, 60 Series Land Cruisers, and 4Runners you can use six stud Six Shooter Knuckles from Trail Gear. For 80 Series Land Cruisers, you can use the high steer, six hole FJ80 Knuckles from HellFire Fabworks.

Trail Gear Six Shooter Knuckle Kit

This kit includes 2 Six Shooter Knuckles, 2 six hole steering arms, and a set of six hole shims. You'll need to provide hardware or buy two Trail Gear Super Metal Knuckle Stud Kits to outfit these knuckles.

These knuckles use six stock-size studs to retain the steering arms. Trail Gear is the only company that makes six stud knuckles for non-80-Series Toyota solid axles. Some of the features of these knuckles are:

A six stud knuckle is one of the strongest upgrades you can do to your knuckles.

Because of the thicker castings, larger gussets, and extra material due to the six stud mounting pad, these are the strongest knuckles you can buy for your Toyota. This is the simplest way to get a stronger stud setup and is worth it especially if you’re planning to buy steering arms at the same time.

The kit includes 2 six stud knuckles, 2 six stud steering arms, and a shim kit. You can outfit the hardware using your existing knuckle hardware (plus extra studs), a couple of Front Range ARP kits, or a couple of Trail Gear Super Metal Stud Kit (built for the Six Shooter).

HellFire Fabworks Six Hole Knuckle Kit for 80 Series Land Cruisers

These six-hole FJ80 knuckles have a larger bolt pattern, use 4 Dana 60 studs, and two allen head bolts to secure the steering arm.

80 Series Land Cruiser axles are a popular SAS axle for Toyota Tacomas or other Toys that need some extra width. 80 Series Birfields have the largest Birfields of any Toyota and some come with a factory locking differential. What they've lacked is high steer options and better knuckle and steering stud strengthening. Not anymore! HellFire Fabworks has released its best version yet of their FJ80 knuckle kit.

The FJ80 knuckle and steering arm kit is pure strength: A fully custom reinforced high steer knuckle, six stud steering arms, and 25mm trunnion pins and bearings.

This kit comes with 2 six hole knuckles, 2 six hole steering arms, steering arm hardware, and 25mm bearing caps/trunnion pins with matching bearings. They have awesome features, such as:

These are very well thought out and at the time of this writing they're on the third iteration of this product. They've had some time to get the kinks out!

Which Should You Choose?

This is a tough question to answer, since the solutions vary based on your budget and your equipment and skills. First, there is no replacement for properly torqued steering arm studs. Any of the above will break if you are half-assing your maintenance (You should always whole-ass your maintenance.).

We would suggest that as you move from the top to the bottom of the list of upgrades that the frequency of maintenance will decrease. That is to say, you’ll probably find that you need to retorque 4 ARP studs more frequently than a knuckle with six studs.

If you’re just plain broke, do the fifth stud mod and clean and reinstall your stock hardware with Loctite.

If you need strength on a budget, we really like ARP studs, properly torqued. If you have problems with loosening, add the 5th stud mod. It requires a little bit of thought to set up the fifth stud, but it should be a fairly bulletproof setup on a stock knuckle.

If you have a little more cash and the skills, the six stud weld-on kit from 4x4Labs is a great strength upgrade. You get to add some beef to your knuckle, you eliminate the shimming concerns of the 5th stud mod, and you get six stud arms.

Of course, the ultimate strength upgrade (and matching price point) is Trail-Gear’s six stud knuckles. This is the only option that gets you a significantly stronger-than-stock reversible knuckle, plus you get six stud steering arms.

Last updated: September 5, 2019